Yet another Bangladesh garment factory tragedy is making headlines. Last November more than 100 workers died in the Tazreen factory fire, some of them because factory managers blocked doors and told them to ignore the fire alarms going off. Last week, at least 400 and perhaps as many as 1,400 people died when a building housing garment factories collapsed. Structural defects were discovered in the building the day before it collapsed and government officials asked factory managers to suspend work. Other businesses in the building shut down but the garment factory owners ordered employees to keep working. Subsequent investigations found that the building had a substandard foundation and that the top four floors had been constructed without permits.

After each tragedy, the government promises to crack down on violations, factory owners promise to do better, and multinational buyers promise to more strictly enforce their codes of conduct for suppliers. And nothing much changes. It definitely costs a lot of money to construct a sound building, but factory owners can do a lot to improve health and safety without spending a lot of money—unlocking emergency exits, providing fire extinguishers that work and training on how to use them, masks for dust, and earplugs for noise. So, as Dylan Matthews asked me in a Wonkblog Q&A last week, why don’t they?

Collective action problems—where no one will move unless everyone moves together—plague the garment industry. It is a highly competitive, low-skill, low-wage, labor-intensive industry that requires relatively little capital investment and is, therefore, highly mobile. Governments are afraid to raise or enforce labor standards because investors and buyers can easily move to another low-wage country. Individual factory owners are afraid to demand higher prices for their goods for fear they will lose business. Multinational buyers are reluctant to offer higher prices because it could erode their profits and disappoint shareholders. And, sadly, many consumers seem to care more about cheap prices than what’s behind the label.

One way forward is for Bangladesh is to work with the International Labor Organization and International Finance Corporation to develop a Better Work program. Better Work is a partnership between those institutions, to help national governments build their capacity to enforce labor laws and to help factories improve productivity. As Richard Freeman and I argued in our book on globalization and labor standards, better working conditions and improved competitiveness are not inconsistent goals. Indeed, there is evidence that a Better Work predecessor in Cambodia has helped open space for improved industrial relations and, through that, to improved conditions, especially around hours, overtime, and health and safety issues.

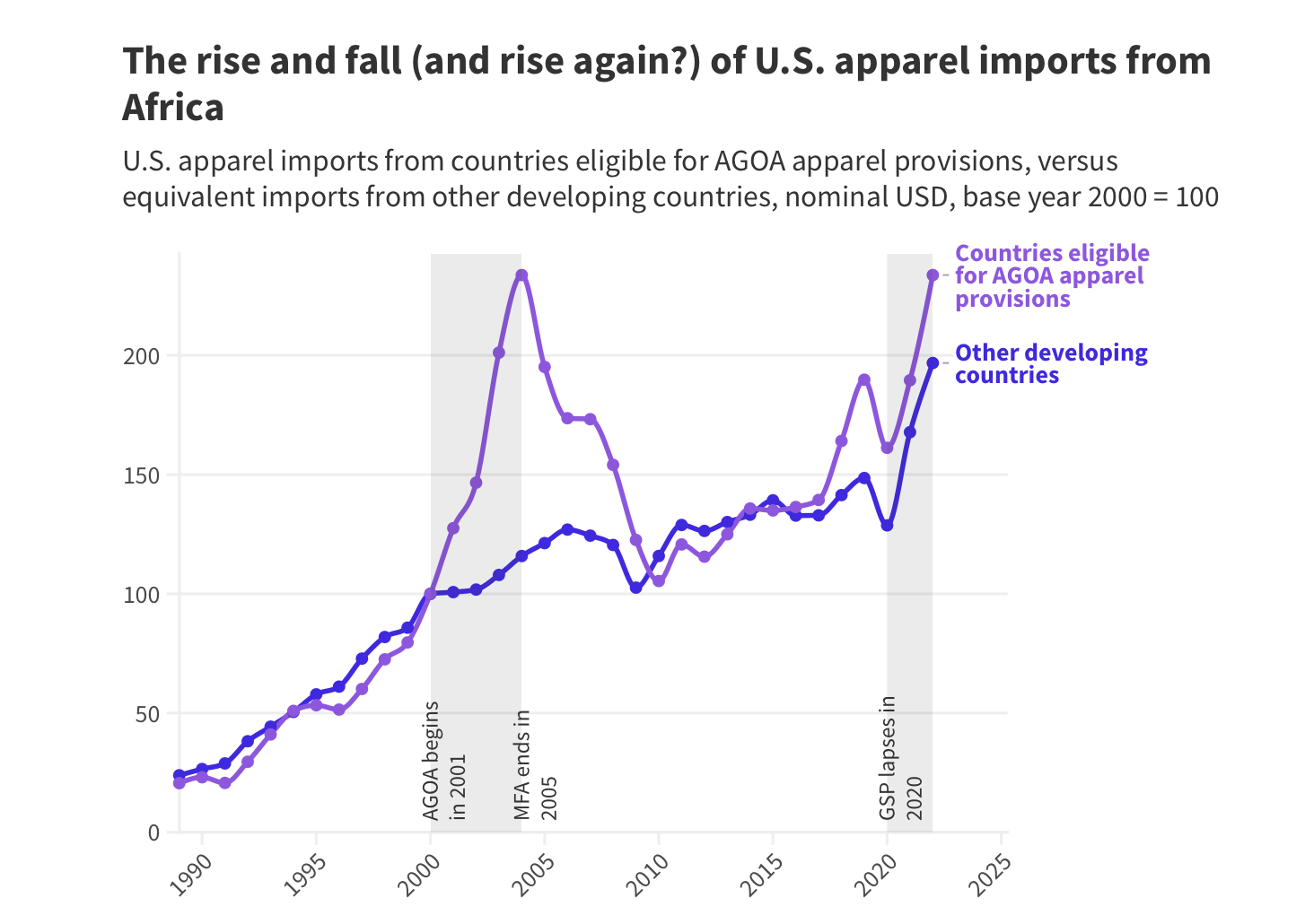

As an incentive to move forward, the United States could offer duty-free, quota-free market access for (most) Bangladeshi exports, if Bangladesh signs on to a Better Work program or takes other tangible steps to improve conditions in its factories. I explained here how this might work, and why it would be more effective than the current threat to withdraw the trivial preferences that Bangladesh receives under the far more limited Generalized System of Preferences program. (As an added benefit, a US embrace of the duty-free, quota-free market access initiative for least-developed countries would contribute significantly to a successful outcome in Bali in December.)

The government arrested the owners of the building and the factory but the signal that it is serious would be stronger if it enforced its laws regularly, not just following a crisis. It will be a long time before Bangladesh has the capacity to do so effectively, however. In the meantime, the government should do more to facilitate workers organizing so they can protect themselves, as BRAC Founder Fazle Hasan Abed argued earlier this week. Ultimately, the Bangladeshi government needs to realize that the country risks being stuck as sweatshop to the world, rather than moving up the ladder by further developing its key asset—workers that are healthy, well-educated, more productive, and can command higher wages.

CGD blog posts reflect the views of the authors, drawing on prior research and experience in their areas of expertise.

CGD is a nonpartisan, independent organization and does not take institutional positions.